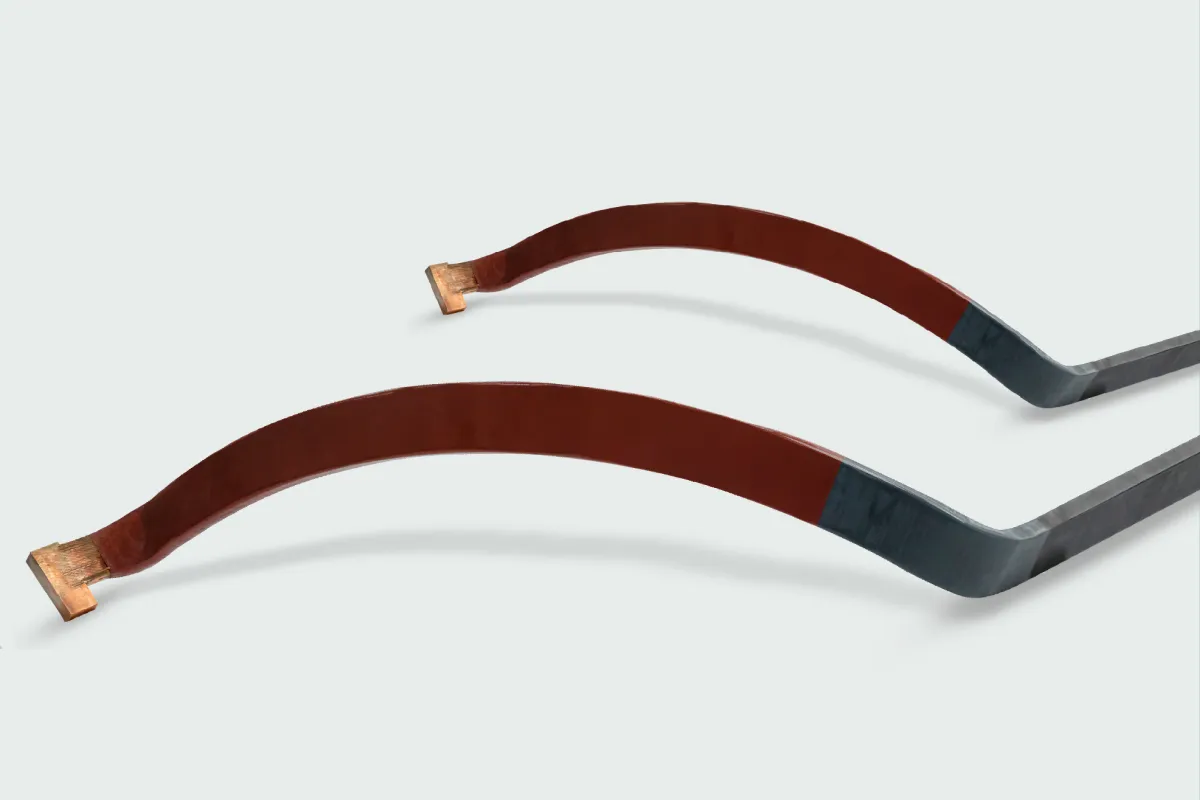

Coral Hybrid Seal®for single bar VPI systems up to 24KV

Coral®PowerSeal™ is a single coil / bar VPI system with an epoxy Anhydride class F insulation. The main characteristic is that the coils / bars are fully cured using a very standard VPI system, using special fixtures to make sure they are dimensional perfect and have no voids in the straight and overhang parts.

Ideally used for High Voltage Turbo and hydro generator coils and bars.

Advantages and special features:

- CoralPowerSeal is a well established and testes single coil / bar Epoxy Anhydride system that is highly trusted and used for many years by the main OEM’s.

- CoralPowerSeal is widely used for motor and generator rewinding as well as for new machines.

- CoralPowerSeal is done using Drying, Impregnation and Curing before insertion, with Coral’s proven VPI systems and is easy to use in repairs either in the field or at our customer’s shop.

- CoralSeal is fully cured in both straight and overhang areas, making sure that there is very little or no air voids, and as such an ideal insulation, with ideal Partial Discharge levels.

Construction of insulation Materials

Conductor covering (Class F) :

- Enamel with Dalgass

- Enamel with Fiberglass covering

Mica tape and subsequent materials:

- Mica putty

- Glassoflex sheet

- Glass mica tape

- Corona shield tape

- Stress grading tape

- Finishing tape/varnish

Impregnation Resin

- Epoxy Anhydride

Standard and special testing alternatives

- Interturn test

- Surge comparison test

- Coil resistance measurement

- IR test IEEE 43:2000

- AC HV Test IS 4722:2001

- Tan delta and Tip up test – IEEE 286:2000

- Surface resistance measurement

- Visual corona test

TYPE TEST:

- Partial Discharge measurement IEEE 1434 : 2014

- Voltage Endurance test IEEE 1043 : 1996 & IEEE 1553 : 2002

- Thermal Cycling test IEEE 1310 : 2012.