About Coral Manufacturing Works

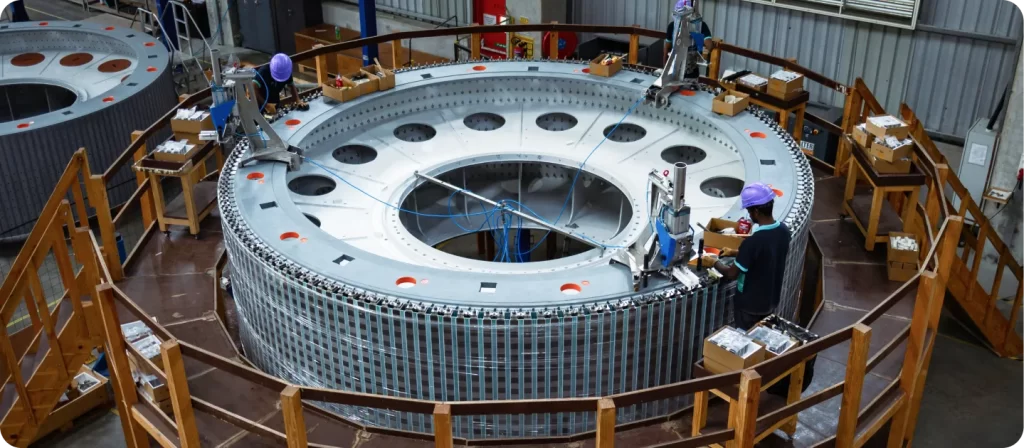

Coral invested INR 800 million in the year 2019 on a dedicated Generator manufacturing facility for Wind, Hydro and turbo generators weighing upto 200 tonnes per generator. Coral Manufacturing works began operations in the year 2021. We are an IMS ISO 9001: 2015, ISO 45001:2018, ISO 14001:2015 certified company.

CMW Plant design

Spanning across a whooping 25 acres, this state-of-the-art facility was planned and designed using global expertise in order to maintain international quality throughout. Coral wanted to build this facility as one of the best facilities in the globe. This facility was constructed in an area of 12 acres and we had to uproot 400 trees, planted them in other areas and we planted 700 new trees in the premises.

Vertical integration

With a vision to maximise vertical integration, a brand new wire manufacturing plant has been setup right next to CMW campus exclusively for the coils. One of the very few facilities in the world with such high levels of vertical integration (wire to coil to generators) enabling a strong foundation for quality, cost effectiveness and sustainability.

25 Acres

of Innovation

and Quality

Our Manufacturing Capacity

Annual Capacity

Manufacturing up to 250 generators per year. (21 Generators per month)

Monthly Production Volume

Delivering a total cumulative power generation capacity of 111 MW.

Heavy-Duty Handling

Capable of handling generator weights of up to 160 tonnes.

Our Expertise & Accomplishments

With an extensive portfolio,

we have successfully manufactured:

- 3MW Model Generators –Total manufactured capacity of 711 MW.

- 5MW Model Generators –Total manufactured capacity of 700 MW.

Heavy Lifting & Crane Infrastructure

Our facility is equipped with 19 high-capacity cranes, enabling:

- Safe and seamless movement of heavy raw materials and finished components.

- Efficient support for large-scale manufacturing and assembly operations.

- Reduced downtime through smooth and synchronised material flow.

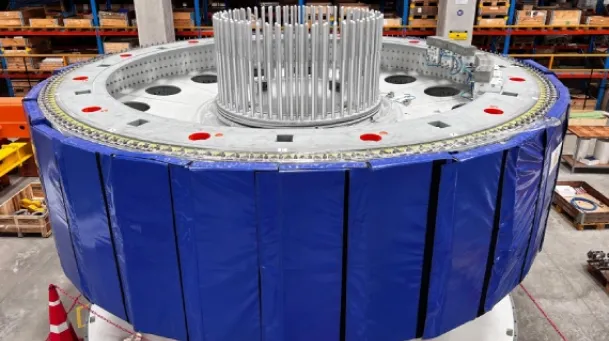

VPI Technology

Facility 1

- Impregnation Tank: 7.2m diameter × 1.5m depth

- Resin Storage: 25,000 liters internal tank

- Fully automated with end-to-end PLC & SCADA control for precision, consistency and traceability.

Facility 2

- Impregnation Tank: 6.3m diameter × 2.5m depth

- External Resin Storage: 20,000 liters

- Fully automated with PLC & SCADA, achieving ultra-low vacuum levels (<0.1 mbar/hr) for superior insulation performance and deep resin penetration

Storage Capacity

- Raw Material Storage for up to 30 generators.

- Finished Goods Storage for up to 30 generators.

Skilled Workforce & Engineering Expertise

Our strength lies in our expert team-engineers, technicians and QC specialists-ensuring flawless execution across all projects.

Our workforce is trained in the latest methodologies and best practices in generator manufacturing, enabling us to continuously innovate while maintaining strict quality control.

Other Highlights About CMW

Solar Energy Utilisation:

Over 40% of our electrical power needs are met through rooftop solar panels, significantly reducing our carbon footprint.

IGBC Certification:

We are in the process of obtaining certification from the Indian Green Building Council (IGBC), which promotes sustainable building practices tailored to India’s climate and construction methods.

Operational Efficiency:

Our efficient systems manage the handling of thousands of raw materials daily, ensuring streamlined operations and minimal waste.

Awarded the Commitment Badge for Excellence in Sustainable Practices.

As part of our strong commitment to sustainability, we have undertaken several initiatives aimed at reducing our environmental impact and enhancing workplace well-being. We have installed a solar power plant with a capacity of 700 kW at CMW and 99 kW at CCI, significantly lowering our reliance on electricity from the grid. 40% of CMW’s power consumption was switched to solar energy. This shift also contributes substantially to CO₂ emissions reduction. To further protect the environment and ensure safety, IPG leak sensors have been installed to detect and prevent harmful gas leaks. In our ongoing efforts to achieve Gold certification from the Indian Green Building Council (IGBC), we are implementing various green initiatives including solar reflective rooftops, fiber-reinforced concrete, an advanced energy management system, a 24×7 water monitoring system, drip irrigation for gardens, and optimal lighting through LED lights. Our workplace is designed to be disability-friendly and features dedicated breakout spaces to support employee wellness.

Trust with our

Certificates

We are backed by more than 9+ industry standards, including ISO, WRAS and FDA.

Get in Touch

Let's Start a Conversation

We're here to help with expert solutions and dedicated support.